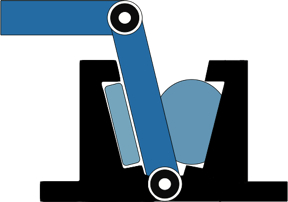

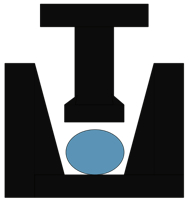

The Windjammer Actuator is a highly versatile, rugged, and long lasting pressure power unit. It is actuated pneumatically or hydraulically and operates effectively under water, immersed in oil, and in dust contaminated atmospheres. Construction of the device consists of (1) a patented solid brass manifold port type fitting, (2) a variable length of special high grade tube with specified inside and outside diameters, and (3) a bolt mounted tail plate.

In actual operation, for example, air under pressure is introduced into the Windjammer unit through the manifold intake which causes the tube to inflate, thereby creating a displacement effect through tube inflation. Upon the release of pressure, the air in the tube escapes through the exhaust port. This action can be repeated in cycle on an almost unlimited basis. Cycles of up to 280 reciprocations per minute are easily achieved.

At the opposite end of the scale, the holding action of the Windjammer can be maintained for a practically unlimited length of time. Maximum operating pressure for most Windjammer units is 100 psi. A special unit, the hydraulic Hydrojammer, manufactured with neoprene and polyester tube accepts operating pressure up to 250 psi.

Product Advantages

The Merriman Windjammer is a simple, versatile, reliable machine conceived and developed using basic principles of dynamic air or hydraulic pressure. The Windjammer is made possible by a uniquely designed and patented manifold which is incorporated into each unit. In combination with high quality, heavy duty tube of special manufacture, it provides the best solution to an extremely broad range of industrial manufacturing and processing, OEM, materials handling, transportation and highly specialized reciprocating, actuating, holding, braking, and positioning requirements.

Unique among actuation devices, Windjammer offers the designer an additional dimension in the use of air and hydraulics because of its physical characteristics. It allows for instance, the application of pressure over wide surfaces and great lengths operating effectively in tube lengths up to 49 feet. Through the combination of a number of units a multiplier effect can be accomplished. Any number of arrangements of Windjammer units in combination can be effected, including use in tandem, series, piggy-backed, stacked in opposition, etc.

The Windjammer is particularly adaptable for use in applications where space is at a premium, when weight is an important factor and/or when initial cost and low operating costs are desired. In the case of space utilization, the physical construction of the Windjammer unit allows it to be applied in extremely difficult space conditions. Its flexible tube construction is particularly adaptable for use on irregular and non-uniform surfaces. Because of all of these physical advantages, Windjammer makes it possible for designers and engineers to perfect equipment of new design and function which costs less, weighs less, requires less space, provides low operating and maintenance costs, long life, and high reliability.

Windjammer provides cost savings from initial unit cost all the way through the cost spectrum to lower maintenance cost. Windjammer units are easy and simple to mount, no matter what type of application is considered. First, because the unit is light in weight, and second, because the basic principle of operation differs so profoundly from the air cylinder, for instance. Original tooling costs are lower in the case of automatic assembly and holding fixtures as complex lever movements and equalizing devices are not required. In the case of the OEM application, equipment can be made more compact and lighter in weight. Used on conveyor equipment, the Windjammer provides braking, diverting, holding, and lifting functions with a minimum of bulk and displacement of valuable space.

Applications Versatility

The uniqueness and physical simplicity of the Merriman Windjammer has resulted in its application across a broad spectrum of actuation requirements. Consequently, as the variety of uses has increased, more and more designers and engineers have realized the practical advantages of Windjammer and perceived an increasing potential for its utilization. The Windjammer is used in such diverse applications as seam welding fixtures and space shuttle production, conveyor systems and form die knockouts, automobile assembly fixtures and flour mills, lift trucks and adjustable clamps, gluing presses and amusement rides.

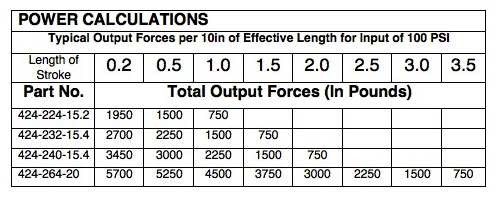

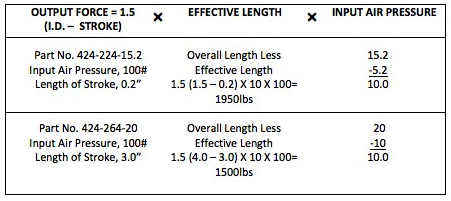

The above table is computed from the formula:

Cost Advantages

Considerable initial unit cost savings are available to customers specifying Windjammers. This is true whether a single unit is required or several hundred. When compared to typical hydraulic air cylinders, for instance, a Windjammer will cost less by two, three, four, or five times, depending upon various factors. Savings of this magnitude per individual unit really mean a lot, especially to the designer or engineer when a system or equipment requires a multiple number of individually located and actuated units.

Maintenance

Simple design and rugged construction are the secrets to Windjammer's long life and easy maintenance. It has no rods and cylinders to fail, no heads, pistons, or bodies to break, and no seals to leak. Oil immersion tests show that the Windjammer can withstand total immersion in lubricating oils for a period of 7200 hours (ten months) with negligible impairment to its operating efficiency. This remarkable device will sustain load cycles in the multi-millions without deterioration of the unit. This means that significant savings in maintenance costs accrue to the user. In the event that replacement is ultimately required, the cost of replacement tubes or a completely new unit is relatively insignificant when compared to expensive hydraulic air cylinders, air motors, etc.